How to Install a Dimmer Switch

How to Install a Dimmer Light Switch

A full day

Intermediate

Less than $20

Introduction

There's more to changing a switch than connecting a few wires. You have to check grounding and box size for a safe, first-class job. It's easy to install a dimmer switch, but make sure to upgrade the wiring if necessary to make it safer and meet Electrical Code requirements. We'll show you how to assure a safe installation.Tools Required

- 4-in-1 screwdriver

- Needle-nose pliers

- Tape measure

- Voltage tester

- Wire stripper/cutter

Materials Required

- Dimmer switch

- Wire connectors

Getting Started: Tools and Power

It doesn’t take long to replace an ordinary light switch with a full-feature dimmer light switch. But while you’re at it, to make your home safer, you should upgrade the wiring to meet the latest requirements of the National Electrical Code. Our step-by-step instructions will show you how to install the dimming switch, concentrating on details that will guarantee a safe installation. Here’s what you can do if your light switch isn’t working.

The tools you’ll need to install a toggle dimmer light switch are inexpensive and will come in handy for all your electrical projects. You’ll need a screwdriver, wire stripper, inexpensive (2 lead wire type) voltage tester and needle-nose pliers to install a dimmer.

Wiring problems and mistakes are all too common, and if left uncorrected have the potential to cause short circuits, shocks and even fires. Here are the top 10 electrical mistakes people make and how to fix what you find.

Project step-by-step (12)

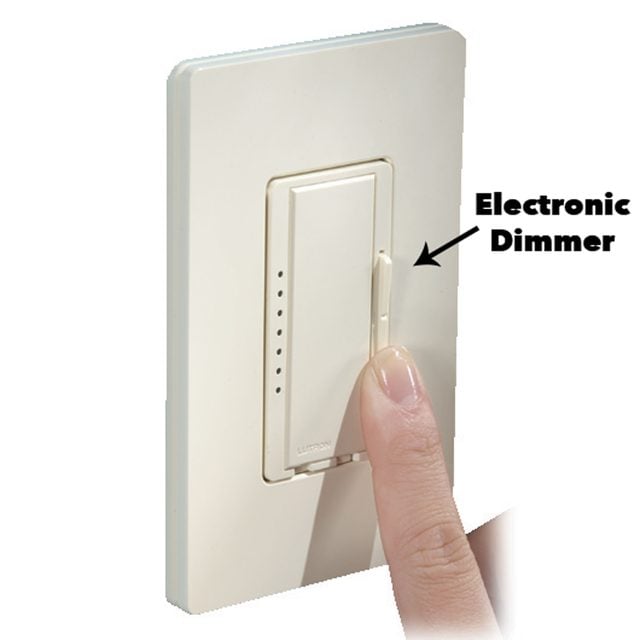

Choosing a Dimmer

There are several types of dimmer switches out there. We show the single switch but there are also three-way dimmers, CFL and LED dimmer switches.

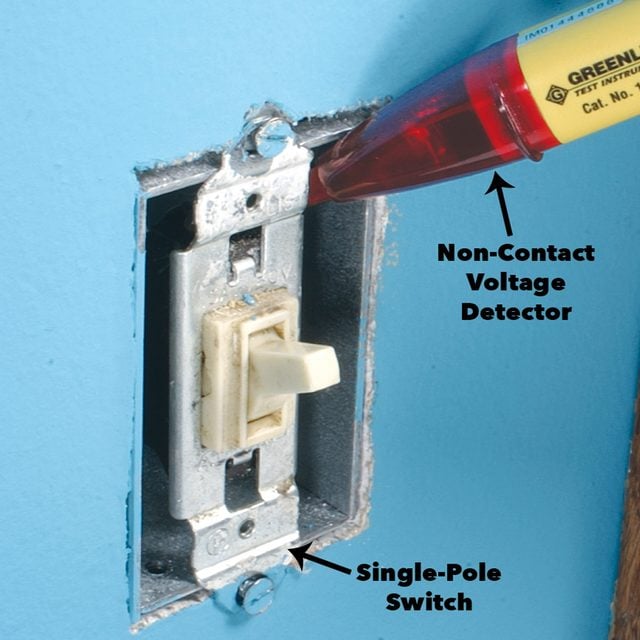

Check for Hot Wires

To begin, turn off the power and double-check for hot wires in the box. Turn on the light and have a helper watch as you switch off the circuit breakers, or unscrew the fuses one at a time until the light goes out. Leave this circuit turned off while you work.

We’re using a non-contact voltage detector to double-check for voltage before removing the dimming switch. We prefer this type of tester because it’ll detect voltage without direct contact with the metal conductor. That’s huge—it means you can check potentially hot wires before you handle them.

Hold the tip of a non-contact voltage detector near each screw terminal to be sure the power is off. After you unscrew the switch and pull it away from the box, probe around inside the box with the detector to make sure there are no other hot wires from another circuit.

Plus, learn how to troubleshoot a dead outlet here.

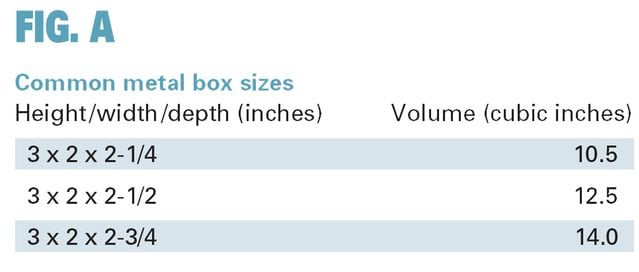

Common Metal Box Sizes

Too many wires and devices stuffed into a box can cause dangerous overheating, short-circuiting and fires. The National Electrical Code specifies minimum box sizes to reduce this risk.

To figure the minimum box size required by the electrical code, add 1 for each hot and neutral wire entering the box, 1 for all the ground wires combined, 1 for all the clamps combined, and 2 for each device (switch or receptacle) installed in the box. Multiply this figure by 2 for 14-gauge wire and 2.25 for a 12-gauge wire to get the minimum box volume in cubic inches.

To help determine the gauge of the wire in your switch box, look at the amperage of the circuit breaker or fuse in the main electrical panel. Fifteen-amp circuits are usually wired with 14-gauge wire and 20-amp circuits require 12-gauge or heavier wire.

Compare the figure you get with the volume of your existing box. Plastic boxes have the volume stamped inside, usually on the back. Steel box capacities are listed in the electrical code. We’ve listed the volume of the most common steel boxes in the chart above.

Make Sure the Box is Large Enough

If you have a steel box, measure the height, width and depth of it to determine the box volume and consult the chart to see if it’s large enough. Plastic boxes have their volume stamped inside. If your box is too small, replace it with a larger one. It’s possible to replace a box without cutting away the wall, but it’s a tricky job. We recommend just removing about a 16-in. square of drywall or plaster and patching it after the new large box is installed.

Tip: If the circuit breaker is labeled “15 amp, ” the wires are probably 14-gauge, or 12-gauge for 20-amp circuit breakers.

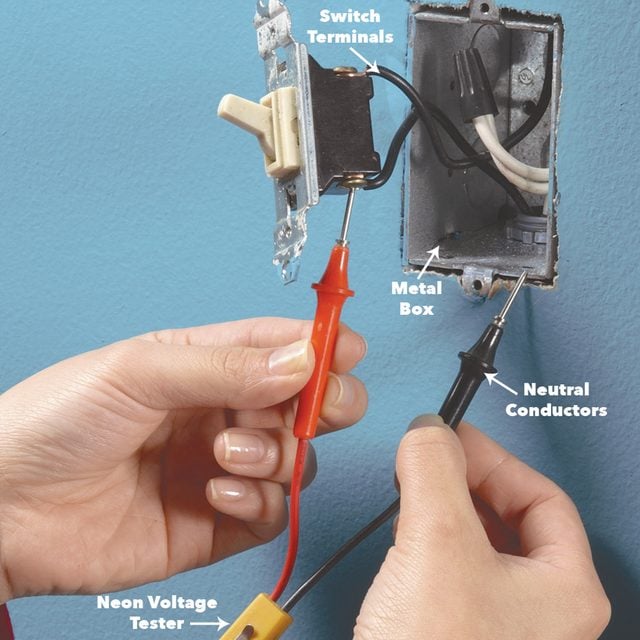

Test Your Ground Before You Connect It

New dimmers have either a green grounding wire or a green ground screw that you’ll have to connect to a grounding source if one is available. Houses wired with plastic-sheathed cable almost always have bare copper ground wires that you’ll connect to the toggle dimmer switch. But test first using a neon voltage tester to verify that the wire is connected to a ground.

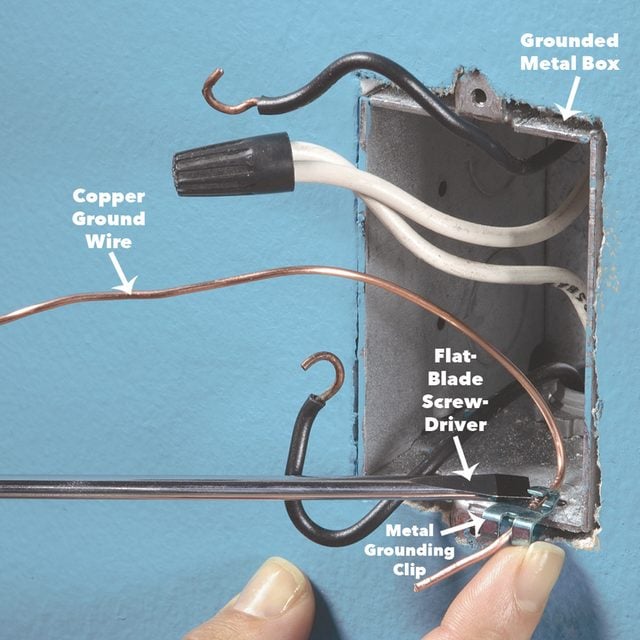

Some wiring systems, like ours, rely on a metal conduit for the ground. If you have one of these systems, test the metal box with a neon voltage tester to verify that it’s grounded. If it is, attach a short ground wire to the metal box with either a metal grounding clip or a green grounding screw screwed into the threaded hole in the back of the box. Then connect it to the dimmer.

If testing reveals your box isn’t grounded, you can still install the dimmer, but you must use a plastic cover plate and make sure no bare metal parts are exposed. Test it again for a ground. Turn the power back on. Then place the leads of a voltage tester between each screw terminal and the metal box. If the tester lights, the box is grounded.

Install the New Dimmer and a Grounding Clip

The steps are basically the same for how to install a switch. Press a grounding clip and 6-in. length of bare copper wire onto the metal box with a screwdriver. Cut away a little bit of drywall under the box to provide clearance for the clip.

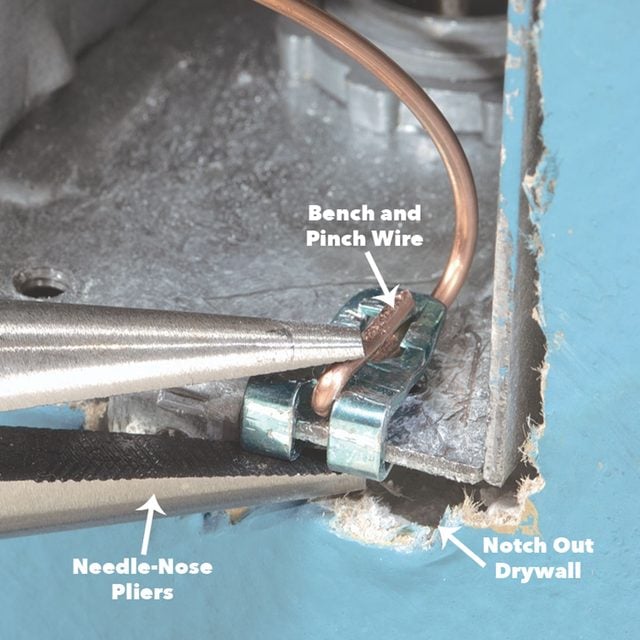

Pinch the Wire End

Bend the ground wire back onto the clip and squeeze it down tight so it won’t interfere with the dimmer switch.

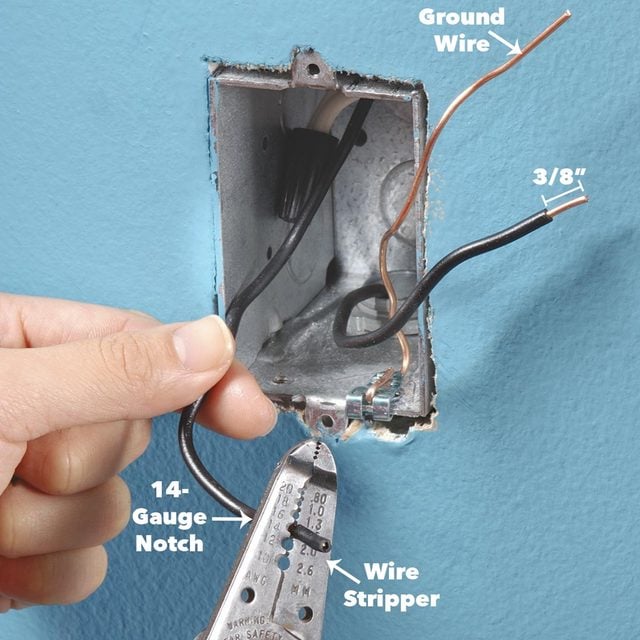

Strip New Wire Ends

Clip off the bent end of each wire with the wire cutter. Strip 3/8 in. of insulation from the end of the wires.

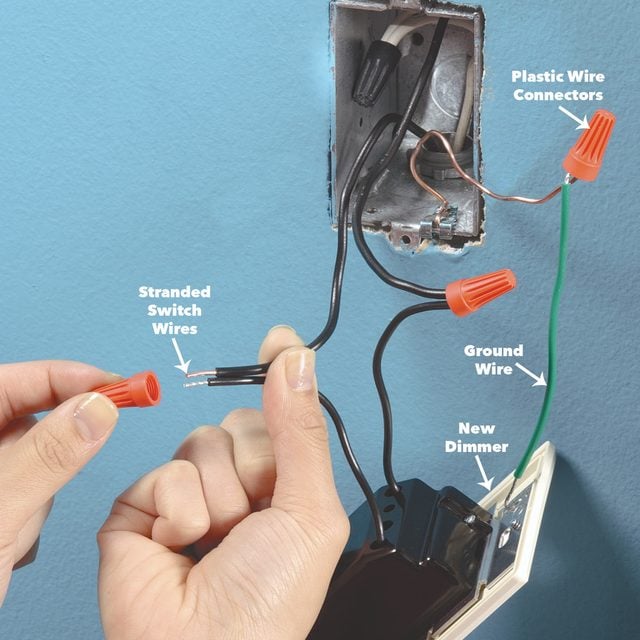

Connect the Wires

Some dimmers, like the one we’re installing, have stranded wires attached. Hold the wires together with the stranded wire protruding about 1/8 in. beyond the solid wire. Match the size of the wire connector you’re using to the size and number of wires being connected. Check the manufacturer’s specifications on the package to be sure. Twist a plastic wire connector clockwise onto the wires to connect them. Stop twisting when the connector is snug.

Other dimmers have screw terminals instead of the attached stranded wires to the new dimmer. For the dimmers with screw terminals, strip 3/4 in. of the insulated covering from the wires in the box and bend a loop in each with needle-nose pliers. Place the loop clockwise around the screw terminals and close the loop around the screws with the needle nose pliers. Then tighten the screws.

Attach Cover Plate for the Wall Dimmer Switch

Fold the wires neatly into the box. Screw the dimmer to the box with the screws provided. Finish the job by installing the cover plate and turning on the power to test the new dimmer.

It doesn’t matter if you reverse the two switch wires to a single-pole dimmer. But if you’re replacing a three-way switch with a three-way dimmer, label the “common” wire (it’ll be labeled on the old switch) when you remove the old switch so you can connect it to the “common” terminal on the dimmer.

Plus, learn how to change a single-pole switch to a 3-way switch.

In most cases, the two switch wires will be some color other than green or white, usually black. But one of the wires may be white if your house is wired with plastic-sheathed cable. Put a wrap of black tape around the white conductor to label it as a hot wire.

Buying a Dimmer Light Switch

If the switch you’re replacing is the only switch controlling the light, buy a standard single-pole dimmer. If the light can be switched on and off from two or more switches, buy a three-way dimmer switch. But you won’t be able to dim the lights from every switch location unless you buy a set of special dimmers with advanced electronics and install one at each switch location.

Watts

Most dimmers are designed to handle 600 watts. Add up the wattage of all the light bulbs you’ll be dimming. Then read the dimmer package to make sure it can handle the load. Heavy-duty 1,000- and 1,500-watt dimmers are also readily available. Read the package if you’ll be installing dimmers side by side in the same electrical box because the wattage rating is reduced to compensate for extra heat buildup.

Finally, you have to use a special device, not a dimmer, to control the speed of ceiling fans and motors. Most fluorescent lights can’t be dimmed without altering the fixture.

Whether you’re looking to add a light fixture or run rough electric for an addition, here are 10 key facts that your electrician wishes you knew.